A Total Solution for Water Supply Plants

A Total Solution for Water Supply Plants

Project Introduction

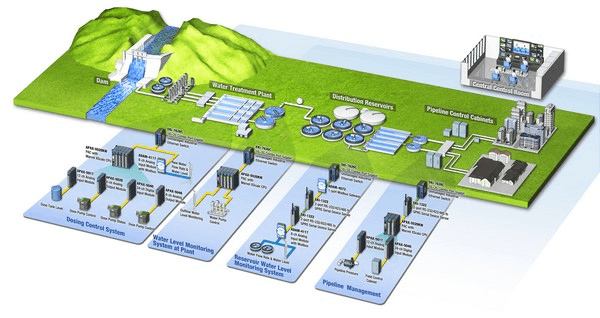

In modern society, water supply plants play an important role in providing daily and clean water to citizens. Essentially, a water-supply system can be divided into three sections: purification, transmission and consumption. The purification of untreated water ensures the water is safe for a variety of purposes. Distribution reservoirs, often built on top of mountains or in the woods, supplement the water transmission system during peak demands and last are the pipes which deliver the water.

Based on this architecture, the traditional operation of a water supply plant consumed a lot of manpower and resources, because the water treatment process needs an extremely accurate dosing control and the outside apparatuses have to be constantly monitored. Therefore, a total solution with advanced technology and robust equipment to control the treatment process and remotely monitor the situations of devices has become an essential measure of water plant management.

System Requirements

The Gongliao water treatment plant is located in the northeast corner of Taiwan and mainly supplies water to Keelung. Its untreated water comes from the river which must go through a series of water treatment processes to make sure it is clean. But there are uncertain conditions that may change the amount of chemicals required e.g. additional rainfall, thereby requiring that the plant has a precise dose-controlled system. Meanwhile, the hardware devices have to withstand the severe operating conditions for this purification steps due to a 24-hour operation.

Secondly, the distribution reservoirs are constructed on a hill which is not only difficult to supply power to but also has a wiring problem. Therefore, the plant wanted to adopt a wireless system to monitor thewater level of the reservoirs and use solar panels to resolve the power shortage issue consequently the monitoring devices have to have a GPRS connection and consume little power to meet the water plant’s needs. As for the pipelines, the most dangerous thing is the pipes bursting because of high pressure. Therefore, the control center needs to collect the pressure data to ensure the pipes remain in optimum condition. In addition, such monitoring systems will be placed in outdoor cabinets which may cause a temperature issue so hardware products have to meet the tough environmental requirements as well.

System Description

Conclusion

As the saying goes, the right approach saves effort and leads to better results. With Advantech’s total solution, the water supply plant successfully implemented an efficient solution with stable operation to manage its water supply process. From the dosing control system to the wireless application, Advantech’s products not only fit its requirements, but won the customer’s trust.

Additionally, unlike the centralized network structure, Advantech’s solution can provide more stability. Any subsystem failure won’t affect others because Advantech offers the distributed architecture to ensure continuity of operation in such abnormal event. Furthermore, all of Advantech’s products have the low-power feature and support the industrial-grade specification to meet hash environment needs.

Although the entire water supply system is complicated, the customer no longer needs to worry about the system compatibility as the entire systems products are provided by Advantech to ensure the best performance. Certainly, the plant saves a lot of manpower and resources through this total solution.

Industrial Automation

Industrial Automation Edge Computing

Edge Computing Industrial Networking

Industrial Networking Intelligent Connectivity

Intelligent Connectivity HMI’S & Panel Meters

HMI’S & Panel Meters Industrial Rugged Mobile Platform

Industrial Rugged Mobile Platform Cyber Security

Cyber Security Oil & Gas

Oil & Gas Power and Energy

Power and Energy Intelligent Transportation

Intelligent Transportation Smart City & IoT

Smart City & IoT Smart Factory

Smart Factory Industrial Cloud Solution (IIoT)

Industrial Cloud Solution (IIoT) Water And Waste Water

Water And Waste Water Building Management System (BMS)

Building Management System (BMS) Security & Surveillance

Security & Surveillance